Lab Start-Up Specialists play a crucial role in establishing and optimizing laboratory environments for research and experimentation. Their expertise encompasses a wide range of tasks and responsibilities that ensure a laboratory operates efficiently, safely, and in compliance with regulations. Here’s an overview of their key functions and areas of expertise.

Laboratory Design and Planning

- Space Utilization: Assessing and designing the layout of laboratory spaces to maximize efficiency and workflow, considering factors like equipment placement, safety, and accessibility.

- Equipment Selection: Advising on the selection of appropriate equipment and instrumentation based on the specific research needs and goals of the laboratory.

Budgeting and Procurement

- Cost Estimation: Assisting with budget preparation for the laboratory start-up, including equipment, supplies, and facility renovations.

- Vendor Relations: Establishing relationships with vendors and suppliers to procure necessary equipment, materials, and services at competitive prices.

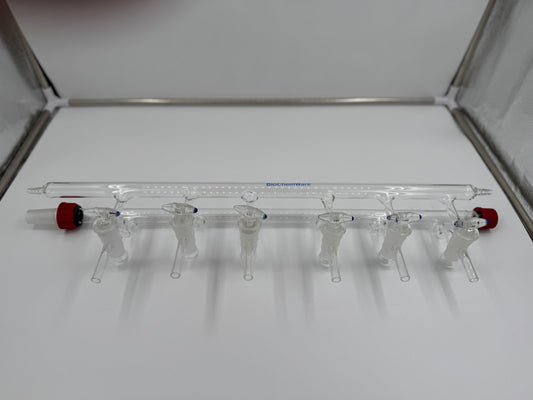

Installation and Setup

- Equipment Installation: Coordinating the installation and setup of laboratory equipment, including ensuring proper calibration and functionality.

Project Management

- Timeline Development: Managing timelines for laboratory start-up projects, ensuring all phases are completed on schedule.

- Team Coordination: Collaborating with various stakeholders, including researchers, engineers, architects, and regulatory agencies, to ensure successful lab launch and operation.

Conclusion

Lab start-up specialists are integral to the successful establishment of research facilities, leveraging their knowledge of scientific processes, regulatory compliance, and project management to create functional, safe, and efficient laboratory environments. Their role not only facilitates the initial setup but also sets the foundation for ongoing research and innovation within the lab.